It’s no secret that the COVID-19 pandemic has impacted the international healthcare supply chain. While this disruption would generally present a challenging situation even in non-pandemic times, the staggering demand for healthcare supplies has only worsened the situation.This was evidenced by an understocked, underfunded national stockpile that...

3PL: How to Cure Growing Pains in Your Healthcare Supply Chain

A Basic Guide to 3PL in Healthcare

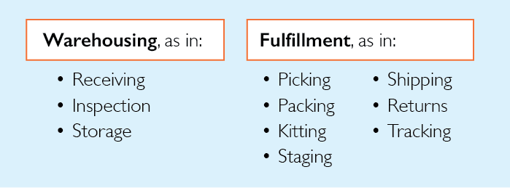

3PL stands for “third-party logistics”; it outsources parts of the supply chain, including:

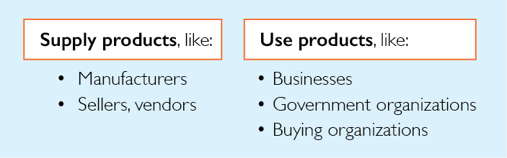

3PL services help move high volumes of products. They’re not primarily for buying or selling of those products—although they can buy and sell as a secondary service. 3PL comes in handy for those who:

3PL often gets mixed up with distribution, fulfillment and warehousing, but it’s not always the same thing. 3PL is a type of distribution; fulfillment and warehousing are types of 3PL.

How Does 3PL Work?

3PL works by offloading the job of supply chain management to a company who specializes in it. It links two parties: those who buy products and those who supply them. 3PL services don’t primarily buy and sell products; they store and ship them.

When Should You Use Healthcare 3PL?

The more volume and variety of items you manage, the more common this becomes. This happens often when businesses grow; their costs often also grow with their revenue. But this doesn’t just happen to businesses—it happens to every organization during large, unusual changes in supply and demand.

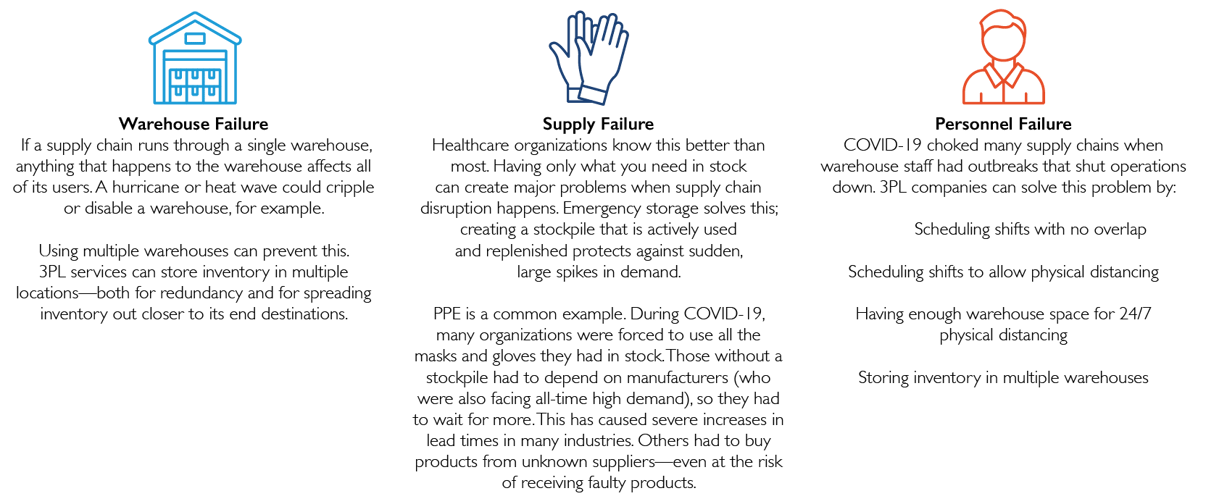

The COVID-19 pandemic was a perfect example. PPE (personal protective equipment) exploded in demand. Face masks, face shields and gloves were needed more than ever. Normally a quick, routine part of inventory management, managing PPE inventory became a job all by itself, creating unexpected costs for countless organizations. Some ordered too much PPE—some too little—and many couldn’t get PPE everywhere it was needed fast enough.

COVID-19 magnified this problem for governments everywhere. They didn't just need more PPE in their inventories; they needed vaccines, vaccination kits, PPE and all the other equipment needed to run mass vaccination sites all over the globe. They also needed to materialize a cold chain for the vaccines.

This caused many health systems and government agencies to outsource the management of their medical supply chain. There wasn't enough money, time or personnel in private and public health organizations to meet the sudden demand themselves.

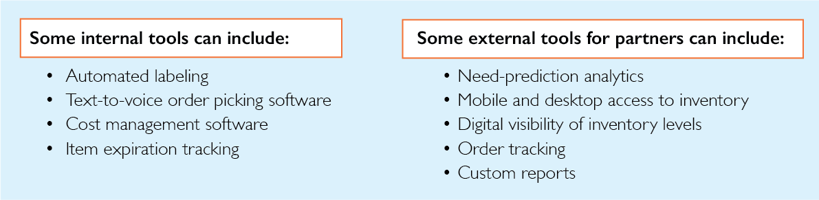

3PL companies often have extensive tools to manage inventory. They prevent errors with internal tools for employee use and external tools for partner use.

3. You need medical and pharmaceutical expertise

3. You need medical and pharmaceutical expertise

• Cold chain management

• Sterility

• Surgical kitting

• Biohazards

• Disaster preparation

• Disaster response

3PL is often the silver bullet for creating redundancy. Adding people, warehouses, and supplies to your inventory can stop disruption from turning into a disaster for your organization.

3PL is often the silver bullet for creating redundancy. Adding people, warehouses, and supplies to your inventory can stop disruption from turning into a disaster for your organization.

Expanding your inventory with a 3PL can take just a few days or weeks in some cases.

This can help control transport costs. But in some cases, it can also speed up delivery tremendously.

This can help control transport costs. But in some cases, it can also speed up delivery tremendously.

Why Partner with Concordance?

Concordance Healthcare Solutions is a nationwide medical distributor and an expert in healthcare 3PL. For over 75 years, we’ve solved problems in the healthcare supply chain like warehousing, storage, transport, sourcing and outfitting new healthcare facilities with equipment, supplies and furniture. Click here to learn more.

A Basic Guide to 3PL in Healthcare

Throughout the pandemic, the country has learned more about the healthcare industry and the vital role each piece plays in the health and safety of our communities. The importance of doctors, nurses and other healthcare professionals has been seen first-hand by many; products like the N95 masks are now household names; the CDC and governmental...

Many locations in the United States that saw a high number of coronavirus infections early on, followed by a decline, are now experiencing a “second wave” of cases,according to Johns Hopkins. As we enter a second-wave of infections, the need for healthcare supplies will continue to grow. High demands for personal protective equipment (PPE)...